LBNF/DUNE pre-excavation work continues above and below ground

Pre-excavation phase involves the rehabilitation of infrastructure created for gold mining operations

Data from the Deep Underground Neutrino Experiment (DUNE) could help physicists explain the origin of matter, witness a never-before-seen particle decay and better understand how black holes form in space—fundamentally changing how we understand the universe.

To prepare for this ground-breaking science, a major construction project is underway to ready the Sanford Underground Research Facility (Sanford Lab) for its role as the far site of Fermi National Accelerator Laboratory’s (Fermilab) Long-Baseline Neutrino Facility (LBNF).

“The Long-Baseline Neutrino Facility is the house for the DUNE experiment,” said David Bressler, one of the Fermilab employees who coordinate the construction work performed by the Kiewit-Alberici Joint Venture (KAJV) at the LBNF far site.

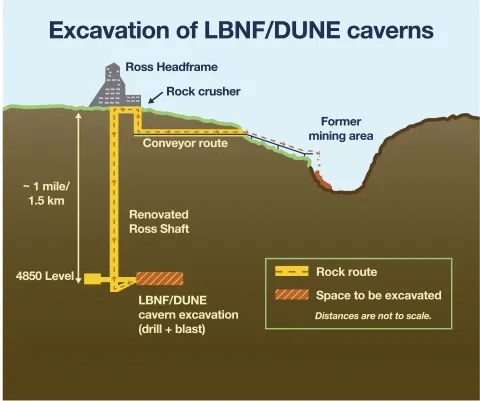

Almost a mile underground, on the 4850 Level of Sanford Lab, massive caverns must be excavated to house DUNE’s Far Detectors, requiring the excavation of approximately 800,000 tons of rock.

Some of the infrastructure needed for excavation and waste rock removal already exists, built for gold mining operations decades ago. Part of the LBNF pre-excavation work requires the reopening, rehabilitation and reinforcement of infrastructure originally created by Homestake Mining Company (Homestake).

Three of these infrastructure components are near completion: Two ore passes that connect the 4850 Level to skips in the Ross Shaft; the Ross Headframe, which must support the skips that bring the rock to the surface; and the tramway tunnel, which will house the conveyor system that will transport excavated rock to its final location.

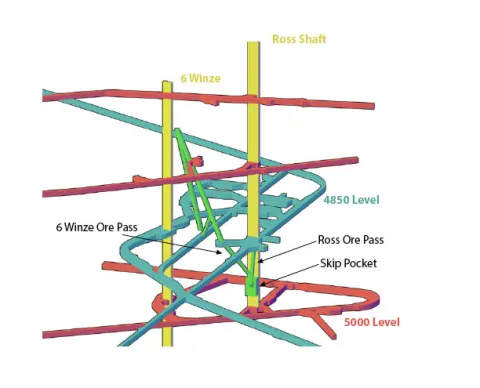

Opening the Ross and 6 Winze Ore Passes

On the 4850 Level, rock must be removed to expand the Ross Station, enlarge access drifts and excavate massive caverns. Earlier this year, crews finished reopening two ore passes, the Ross and 6 Winze Ore Passes, that connect the 4850 Level to a skip pocket in the Ross Shaft. Functioning similarly to a laundry chute, these passageways allow waste rock to be dumped into skips and hoisted up the Ross Shaft, with control gates to manage the flow rate of the rock.

“Having two ore passes gives us flexibility as we plan the sequencing of the excavation,” said David Vardiman, geotechnical project engineer at Sanford Lab.

Opening the ore passes required crews to muck out 1,700 cubic yards of space that had been filled in since the passes were last used by Homestake circa 2001. The crews installed ground support throughout the ore passes and reinforced the area surrounding the Ross Shaft.

Strengthening the Ross Headframe

The Ross Headframe and Shaft structures are dedicated to the LBNF/DUNE project, hoisting waste rock during excavation and transporting workers, researchers and equipment for decades to come. Sanford Lab and LBNF crews worked to rehabilitate the 5,000-foot Ross Shaft over the past several years. With this project nearing completion, they are now focusing on strengthening the Ross Headframe.

“The Ross Headframe, a lattice structure constructed in the 1930s, was a tremendous undertaking at the time,” said Bressler.

Albertson Engineering, Inc. designed a model of the headframe and identified portions of the structure that would need to be strengthened. Additional safety features, such as a dogging system that can stop the cage that goes up and down the shaft in the event of an emergency, were installed. Nearly a thousand pieces of steel reinforcement have been added to the structure, including new side panels, crash beams and high strength bolts. The foundations of the headframe are also being reinforced.

Rebuilding the tramway and conveyor

Once rock is hoisted up the Ross Shaft, it will be crushed in the Ross Crusher and deposited onto a conveyor system. The conveyor will transport rock through the tramway tunnel and into the Open Cut, an open pit mining area excavated by Homestake in the 1980s. To support the conveyor system, crews rehabilitated the tramway, a three-quarter mile tunnel that was used by Homestake to transport ore at the end of the twentieth century.

“The initial goal was to make the tramway safe for future work,” Bressler said, explaining that the majority of the tramway is an underground tunnel. “That included rock bolting and meshing the underground section. The crew also poured concrete to elevate the track and brought in water, power and compressed air.”

Work on the conveyor system is underway. The installation of foundations for 24 structural bents, or support towers, began in December 2019. These towers of differing heights will elevate the conveyor over the Route 85 highway in Lead before the system reaches the Open Cut.

Future work includes refurbishing the three-story-tall rock crushing system next to the Ross Headframe and establishing the power infrastructure for operating the LBNF/DUNE experiment, which will include 70,000 tons of liquid argon cooled to minus 300 degrees Fahrenheit (minus 184 degrees Celsius).

The ongoing work is a multifaceted collaboration between Fermilab, KAJV and its subcontractors with support from Sanford Lab.

"This project has been a huge partnership,” Bressler said. “Sanford Lab staff has been gracious and helpful all the way, supporting the work and providing priceless institutional knowledge about the existing facility.”

Sanford Lab is operated by the South Dakota Science and Technology Authority (SDSTA) with funding from the Department of Energy. Our mission is to advance compelling underground, multidisciplinary research in a safe work environment and to inspire and educate through science, technology, and engineering. Visit Sanford Lab at www.SanfordLab.org.

The Office of Science of the U.S. Department of Energy is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit energy.gov/science.