LZ acrylic tanks arrive

Experiment reaches another major milestone with delivery of critical components

Engineers working on the design of LUX-ZEPLIN (LZ), a second-generation dark matter detector, celebrated the arrival at Sanford Lab of two large acrylic tanks. Wrapped tightly in layers of protection, the tanks didn’t look like much, but they will play a critical role in the experiment.

“This is really exciting and fun to see,” said Susanne Kyre, a mechanical engineer at the University of California Santa Barbara (UCSB) who worked with researchers to design the acrylic tanks. “As an engineer, you draw things up and you have certain expectations. But seeing it completed and standing next to it is very different.”

LZ, a second-generation dark matter experiment, will pick up where its predecessor, the Large Underground Xenon (LUX) experiment left off, continuing the search for WIMPs (weakly interacting massive particles) using a much larger and far more sensitive experiment.

The acrylic tanks, or more precisely the liquid scintillator inside the tanks, are crucial in bringing the experiment to a new level of sensitivity—100 times greater than LUX—by identifying neutrons, which can mimic dark matter signals.

“Recent dark matter searches have found that neutrons can be a pernicious background,” said Carter Hall, LZ spokesperson and professor of physics at the University of Maryland. “The acrylic tanks and their liquid scintillator payload will provide a powerful neutron rejection signal so LZ is not fooled.”

Finding the right fit

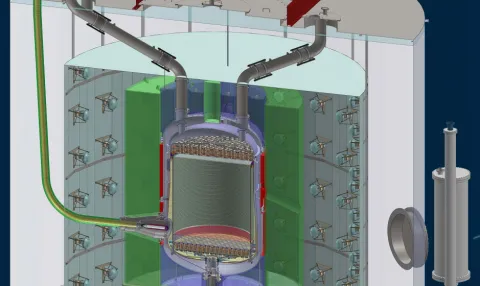

Like all materials used in sensitive physics experiments, the acrylic tanks have to meet certain requirements. In all, there will be 10 acrylic tanks completely surrounding the cryostat, which will be filled with 10 tons of ultra-dense, purified liquid xenon.

“Ideally, we would have liked to have one tank built and fabricated—inside the water tank,” said Sally Shaw, a post-doc with the UCSB. Shaw oversees the simulation of the acrylic tanks—or outer detectors—characterizing its performance and efficiency and planning its calibration and commissioning.

But logistics and cleanliness protocols made that cost prohibitive, Shaw said. Instead, they designed 10 pieces that have to fit very precisely together. Oh, and the material can’t interact with the liquid scintillator and has to be transparent, so researchers can see the signals they are looking for.

“There are very few materials that meet those requirements,” Kyre said. “Acrylic is one—and it has the added value of being very low in background.”

The collaboration turned to Reynolds Polymer, a world-leading acrylic and polymer materials production company that is most known for its acrylic aquariums and swimming pools, as well detectors for physics experiments around the world.

“The shape of our tanks is very complicated, and the dimensions have to be almost perfect,” Kyre said. “Each of the four side tanks is curved and they have to intersect with other curved walls. There were challenges, but Reynolds took our needs and concerns very seriously and came through with flying colors.”

Moving the tanks

The first two side acrylic tanks arrived at Sanford Lab inside a climate-controlled semi-tractor trailer, nestled inside bright pink steels frames and wrapped snuggly in several layers to further protect the tanks from damaging UV rays, to absorb shock and to mechanically protect the tanks. But weather was a big concern—especially considering the tanks were being delivered in October. To Lead, South Dakota.

“We set the temperature in the truck to ensure it didn’t change much between Grand Junction (Colorado) and Lead. If those tanks get cold on the outside but stay warm on the inside, it can cause stress on the material,” said Jeff Cherwinka, LZ project engineer from the University of Wisconsin.

Each of the acrylic tanks measure 12.3 feet tall, 7.5 feet wide and 3.4 feet thick and weigh 1,500 pounds. Additionally, the steel frames weigh 2,740 pounds. So, moving them—both on the surface and underground—poses certain challenges.

“There were several things we had to do to prepare it for shipment to ensure it was clean and arrived safely,” Cherwinka said. Upon arrival, Cherwinka, other engineers and Sanford Lab staff were on hand to unload it, even doing a practice run before unloading the real thing.

“It went really well. We have a very experienced team who make it all look easy—even when it’s not,” he added.

The next move? To the 4850 Level. The size of the tanks means they will have to be suspended below the cage and slowly moved down the Yates Shaft—a process that could take several hours from start to finish—then maneuvered on a “rotisserie-style” device through the Davis Campus to the Davis Cavern then into the water tank. The device will allow freer movement of the tanks as they are moved through the drift and around other static equipment.

Preparing the space

The 72,000-gallon water tank will house a dark matter experiment that is 30 times larger than its predecessor and has hundreds more components—including the acrylic tanks that will surround the cryostat.

The opening to the water tank is about 8 feet in diameter and the cryostat, which sits just below it, is just over 6 feet. So, the acrylic tanks, which are among the last components to be fitted onto the experiment, have to go in first. As they travel through the Davis Campus and into the water tank, the acrylic tanks will shed their onion-like layer until only the protective covering, which protects the material itself from damage, remains. The tanks will be strapped against the walls until the collaboration is ready for them.

“We can’t start the assembly of the cryostat until these acrylic tanks are in place,” Cherwinka said. “But first we have to get them down the shaft and into the water tank. It’s a big deal. When we get the first one down, I’ll have infinite confidence we can get all four in the water tank.”

Next steps

“The arrival of the acrylic tanks is a major milestone for the LZ project,” said Murdock “Gil” Gilchriese, LZ project director. It marks the second time in just the last few months that LZ has had cause to celebrate.

In May, the inner and outer cryostats arrived at Sanford Lab. The outer spent five weeks being fully assembled and leak-checked in the Surface Assembly Lab (SAL) cleanroom. It has now been disassembled and packaged for transportation from the surface to the underground location at SURF. The inner cryostat will undergo the same procedure.

Once the cryostats are inside the water tank, the acrylic tanks will be fitted around it and clamped onto a platform. It’s an important step in a long journey that began even before LUX was installed in the same water tank in 2012 and one that pushes the collaboration closer to its goal: the direct detection of dark matter.

For more information about LZ and the LZ collaboration, visit http://lz.lbl.gov/.

Major support for LZ comes from the DOE Office of Science’s Office of High Energy Physics, South Dakota Science and Technology Authority, the U.K.’s Science & Technology Facilities Council, and by collaboration members in South Korea and Portugal.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit the Office of Science website at http://science.energy.gov.

The Sanford Underground Research Facility’s mission is to enable compelling underground, interdisciplinary research in a safe work environment and to inspire our next generation through science, technology, engineering and math education. For more information, please visit the Sanford Lab website at http://www.sanfordlab.org.