David Woodward, a researcher on the LZ experiment, works on the test cryostat.

In preparation to test the xenon circulation system for the LUX-ZEPLIN (LZ) dark matter experiment, David Woodward carefully positioned a tower holding a stainless-steel test cryostat. The LZ collaboration will circulate liquid xenon through the test cryostat to ensure the system will work properly when the experiment begins operations next year.

“We aren’t looking for dark matter with this test. But we do want to make sure all of our systems work the way they are supposed to,” said Woodward, a post doc at Penn State University.

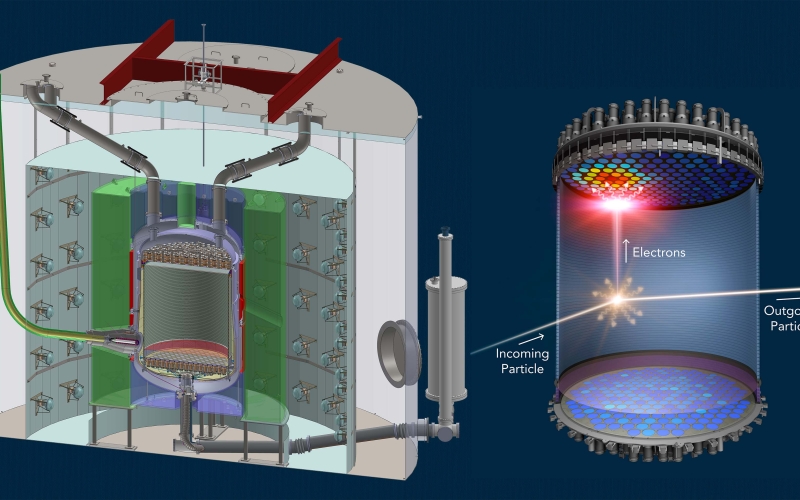

The circulation system is, perhaps, the most critical component of the LUX-ZEPLIN dark matter experiment. LZ will use 10 tons of liquid xenon to look for WIMPs—weakly interacting massive particles—and that xenon must meet very high radio-purity standards to eliminate background noise. To achieve and maintain this level of radiopurity, the xenon must be continuously removed, purified and reintroduced to the LZ detector, or circulated, during operation.

The circulation system sits outside the water tank, which will house LZ. It’s a complicated system comprised of thousands of components: circulation compressors, tubing, wiring, sensors, all of which will connect to the actual experiment. The inner cryostat will hold the xenon, which will be fed into the experiment through an opening at the bottom of the water tank then continuously circulated.

The test cryostat is designed very much like the real inner cryostat. It is the same height and has many of the same components; however, it is not as big around.

“One of the goals of the test is to make sure we can circulate the xenon at the correct rate,” Woodward said. “That’s definitely possible even with a test device that isn’t exactly the same size as the actual device. It helps us understand whether the flow will work correctly—to make sure we can get the xenon to circulate all the way to the top of the actual cryostat,” Woodward added.

The tower holding the test cryostat was positioned precisely to ensure the xenon transfer lines, which have a fixed length, will reach the real LZ cryostat once the experiment is actually running. The collaboration will monitor the system; however, there are some things they won’t be able to know, unless they can physically look inside the test cryostat. To do that, they added a glass view port on the top of the device.

Why do they need a viewport?

“The xenon has to stay at a certain temperature to remain liquid (minus 169.2 degrees F),” Woodward said. “If it doesn’t stay cold enough, it can revert back to gas. Gas creates bubbles, so if that happened, we could see the bubbles. But, really, we don’t want to see anything—we want this test to be boring and just see a nice flow of the liquid xenon. But if something did happen, we could see it.”

The team will test the circulation system for several months, or as long as possible, Woodward said, to ensure it is working correctly. Then the test cryostat will be unhooked and removed. By end of summer this year, the actual cryostat will be installed, with operation of the experiment expected to begin in early 2020.

“This test is very important to our experiment, a very important check for the next phase,” Woodward added.

Facts and figures

The test cryostat is made of stainless steel, whereas the one that will be used in the experiment is made of titanium. Although it is as tall as the actual cryostat, it is much smaller in diameter. “We are not looking to collect physics data with the test vessel, so we don’t need the volume,” said Woodward.

In building the test vessel, the team followed fairly closely the cleanliness protocols for the actual vessel that will be used. It's important that we have the purest materials possible to minimize radioactive backgrounds in the actual experiment. “We don’t want this test to dirty the real circulation system, so we had to construct it inside the surface clean room then seal it up before bringing it underground,” Woodward said.

The test cryostat arrived from Penn State where it was initially assembled inside a cleanroom. At Sanford Lab, the test cryostat was cleaned and prepared for use underground. Now, it is underground where it is being used to test the circulation system. “That’s how we’ll know if the system is working.”

By the numbers:

- 100 inches: The height of the inner cryostat

- 10 feet: The height of the outer cryostat

- 10 tons: The amount of liquid xenon that will be used inside the inner cryostat

- 70 kg: The amount of liquid xenon used to test the circulation system